vibration

& ultrasound

Ultrasound Inspections for Mechanical System Integrity

DETECT DEFECTS WITH

ULTRASOUND

Ultrasound is considered the first line of defense for finding defects that can lead to asset failure. Costly compressed air leaks, bearing over/under lubrication, electrical safety. Take the guess-work out of your routine PMs.

Let our experienced technicians provide accurate and reliable inspections to keep your operations running smoothly.

ULTRASOUND Analyis

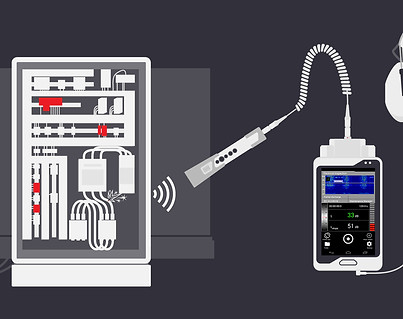

Typical applications for ultrasound include compressed air & gas leak detection, bearing inspection and real-rime lubrication, motors, gearboxes, electrical inspection of energized electrical equipment, valves, hydraulic applications and steam traps

ULTRASOUND IN PREDICTIVE MAINTENANCE

A Powerful Tool

Ultrasound inspections are a non-destructive testing technique that use high-frequency sound waves to detect changes in the structure of materials. They are widely used in a variety of industries, including manufacturing, transportation, and energy production. Ultrasound inspections can detect problems that may not be visible to the naked eye, such as cracks, leaks, and other defects.

Ultrasound inspections are typically performed by trained professionals who use specialized equipment to transmit and receive sound waves. The results of an ultrasound inspection can be used to identify potential problems before they become more serious, which can save you time and money in the long run.

There are many benefits to ultrasound inspections, including:

-

Early detection of potential problems: Ultrasound inspections can identify potential problems before they become more serious, which can help prevent costly downtime and repairs.

-

Improved safety: By detecting potential problems early, ultrasound inspections can help prevent accidents and injuries caused by equipment failure.

-

Increased efficiency: By identifying problems early, ultrasound inspections can help improve the efficiency of your equipment and reduce energy consumption.

-

Cost savings: By detecting potential problems early, ultrasound inspections can help reduce the cost of repairs and maintenance.

After having an ultrasound inspection performed, you might find a variety of issues, such as:

-

Bearing defects: Ultrasound inspections can detect defects in bearings, which can lead to equipment failure if not addressed.

-

Leak detection: Ultrasound inspections can detect leaks in pipes and other equipment, which can help prevent environmental damage and reduce the risk of accidents.

-

Electrical faults: Ultrasound inspections can detect electrical faults in motors, transformers, and other equipment, which can help prevent fires and other safety hazards.

At Dynamic Thermal Imaging, we use the latest ultrasound and vibration analysis technologies to provide our clients with accurate and reliable predictive maintenance solutions. Our experienced technicians are trained to detect potential problems before they become more serious, which can help prevent costly downtime and repairs. Contact us today to learn more about our ultrasound and vibration analysis services and how we can help keep your equipment running smoothly.